Bishop Water Technologies and Neo Chemicals & Oxides have launched a new rare earth-based coagulant in Canada.

According to Bishop Water Technologies, this solution can help wastewater treatment plants achieve ultra-low phosphorus limits, as low as 0.07 mg/L, without the need for costly tertiary filtration systems.

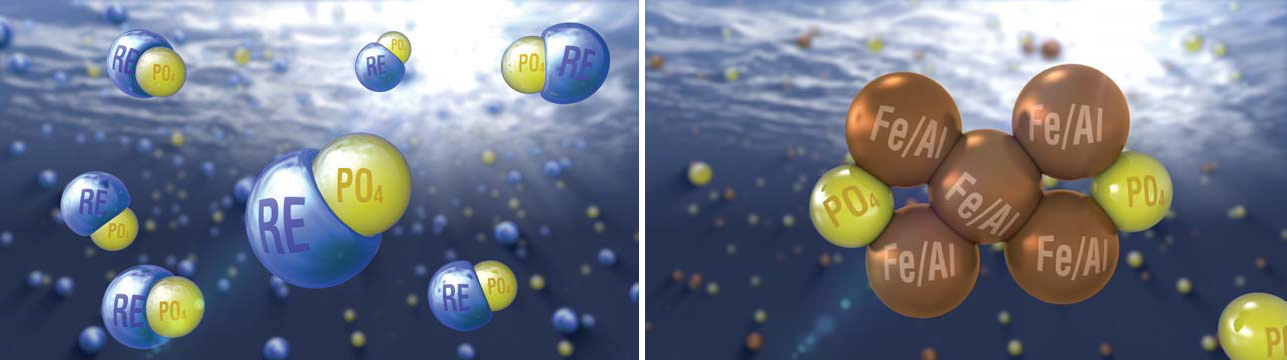

Neo RE300 is a rare earth-based coagulant that offers a way to achieve significant phosphorus reduction in treated effluent by replacing conventional ferric- or alum-based coagulants with this advanced treatment technology. Neo RE300 could also help to significantly enhance the efforts of regulators and conservation authorities working to protect sensitive water bodies from eutrophication and algae blooms linked to phosphorus discharge, according to Bishop Water Technologies.

Neo RE300 outperforms conventional coagulants, according to Bishop Water Technologies, because the rare earth minerals it contains bond more tightly to phosphorus to form a denser, heavier precipitate that settles about two times faster than alternatives. This not only improves clarifier performance, but also dramatically reduces both the amount of coagulant used and the volume of sludge produced to achieve high phosphorus removal.

“Neo RE300 is a game-changing technology that could help communities achieve stringent phosphorus limits without spending millions in capital costs for filtration equipment and ongoing operating costs,” said Kevin Bossy, chief executive officer of Bishop Water Technologies. “Many wastewater treatment plants already have chemical feed equipment in place as part of their phosphorus reduction programs that are capable of delivering Neo RE300. Enhancing the performance of this equipment and achieving ultra-low phosphorus levels could be as simple as replacing the current ferric- or alum-based coagulant with Neo RE300.”

“Over 50 wastewater plants in the United States are already using Neo RE300 to achieve stringent phosphorus limits, optimize their treatment processes, and protect sensitive aquatic ecosystems from excess phosphorus discharge,” said Alan Weber, general manager of water technologies at Neo Chemicals & Oxides, an affiliate of Neo Performance Materials, Inc. (TSX: NEO). “We are confident that Neo RE300 will deliver the same benefits to Canadian wastewater treatment plants, and we look forward to working with Bishop Water Technologies as our representative in this important marketplace.”

According to Bishop Water Technologies, the Neo RE300 rare earth-based coagulant also provides a number of other benefits that can help wastewater treatment plants achieve significant operational efficiencies and cost savings over conventional coagulants, including:

- Reduce sludge production by up to 70 per cent.

- Achieve up to 30 per cent higher attained solids in dewatered sludge.

- Maintain chemical dosing and performance in temperatures as low as -40oC

- Inhibit the formation of struvite.

- Safer for the environment; consistently passes Whole Effluent Toxicity testing.

- Safer for operators; rated non-hazardous.