Researchers at the University of British Columbia have developed a low-cost membrane that effectively separates oil and water on demand. The technology could pave the way for faster cleanups of oil spills and improved treatment of industrial wastewater in the future.

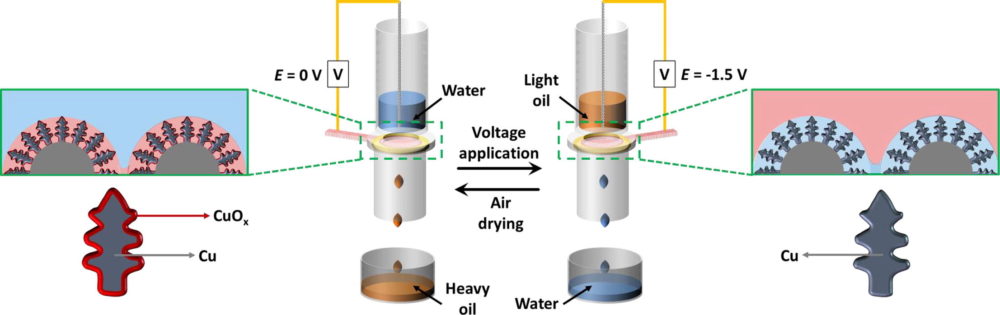

The research will be published in the June 30th edition of Applied Surface Science, titled: On-demand oil-water separation via low-voltage wettability switching of core-shell structures on copper substrates. The work describes a membrane that consists of a treated copper mesh that can be switched from oil-removal to water-removal mode simply by applying an interval of voltage from a regular alkaline battery. In the oil-removal mode, heavy oil passes through the mesh while water is retained; in water-removal mode, the mesh allows water to pass through while retaining light oil. This enables users to achieve almost complete separation of both light and heavy oils from water using a single membrane.

“This technology offers an effective and eco-friendly way to reduce the negative impacts of oily water and wastewater, which are being produced by domestic, municipal, and industrial processes every day,” said Chun Haow (Bryan) Kung, a chemical engineering master’s student at UBC who led the study. “Other oil-water separation methods, such as those that rely on skimming, combustion, and solvents, are either too expensive, too cumbersome, or inefficient.”

While there are other membrane treatments that can switch from oil removal to water removal, they often rely on toxic, unstable chemical coatings that take time to activate. They also tend to produce relatively impure oil and water that need to be processed further, said Kung.

“Our membrane is free of additives and is capable of achieving at least 98 per cent purity for the separated oil and water,” said Kung. “It needs a single electrical charge to switch operations and requires no special equipment or conditions.”

Kung and his colleagues prepared the membrane by immersing a simple copper mesh in an electrolyte solution and applying two small voltages for a total of two minutes. The process changes the surface structure of the mesh and gives it the ability to switch back and forth from attracting water and repelling oil to attracting oil and repelling water.

To test the mesh’s robustness, the team also put it through 30 consecutive separation cycles using mixtures containing both light and heavy oils.

“Oil-contaminated water continues to be a major problem around the world, with an estimated two million tonnes of oil being discharged into bodies of water each year,” said the study’s senior author, Walter Mérida, a mechanical engineering professor at UBC and the director of the university’s clean energy research centre. “Our hope is that this membrane ultimately leads to a better way to treat our water and protect our environment.”