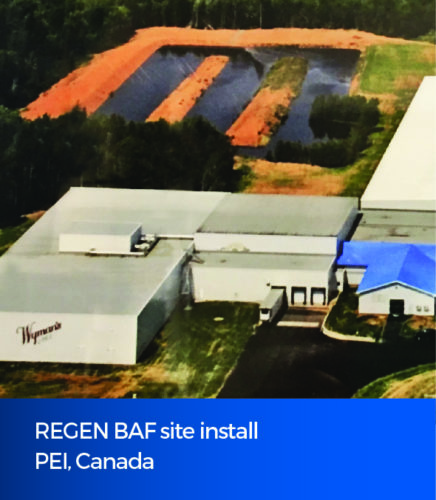

Location: PEI, Canada, July 2017

There are over 6,000 wastewater lagoon treatment systems currently in operation across North America. Lagoon infrastructure is a reliable and robust solution for wastewater treatment. Upgrade options are required for lagoons due to increasing capacity requirements or more stringent discharge standards.

The REGEN wastewater lagoon treatment solution incorporates a low-complexity, fixed-film wastewater treatment process that is easily added in series or parallel to existing lagoon wastewater infrastructure.

Low-energy operation allows for potential integration with renewable energy sources. Chemical-free operation allows for low-complexity and cost-effective operation.

The latest REGEN solution has been validated at Wyman’s of PEI’s blueberry processing facility in Morell, Prince Edward Island.

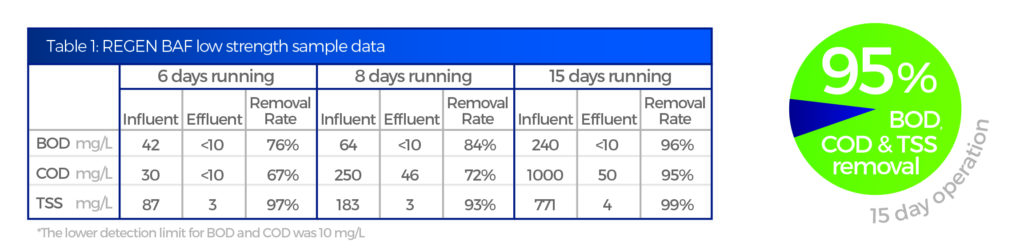

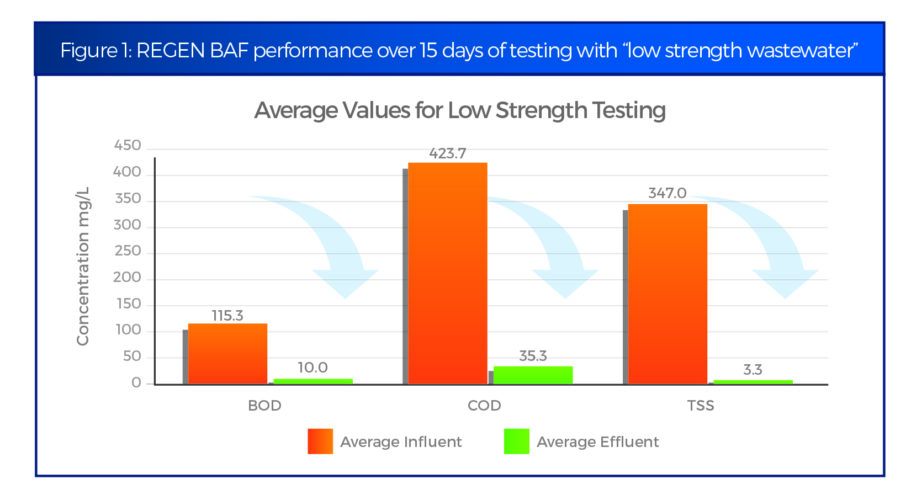

Results:

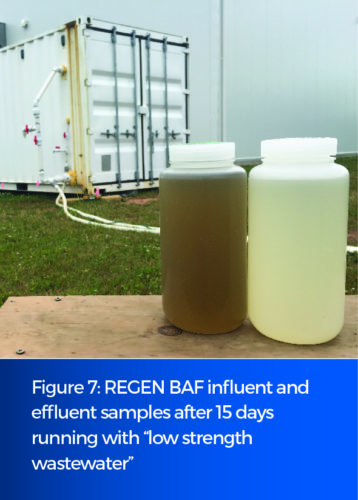

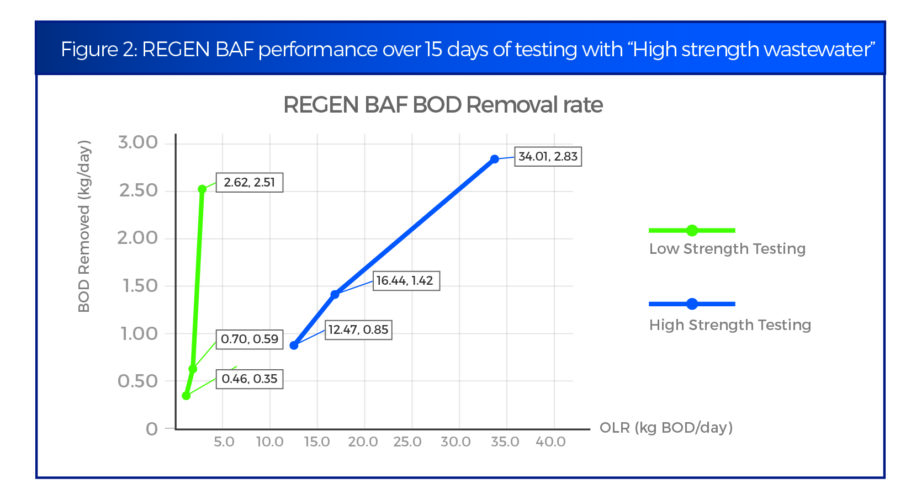

The pilot system removed more than 10 kilograms per day of Chemical Oxygen Demand (COD) from the lagoon. The Biochemical Oxygen Demand (BOD) concentration was reduced from 240 milligrams per litre to less than 10 milligrams per litre. Removal rates of 95 per cent or more were observed for COD, BOD, and Total Suspended Solids (TSS).

A full scale, 40-foot ISO container system would remove more than 10 kilograms of BOD or more than 40 kilograms per COD per day from the lagoon and could be operated for wastewater polishing or in recirculation.

The REGEN BAF testing at Wyman’s proved that the system can supplement underperforming lagoons. Running the system with it discharging back into the lagoon helps to reduce the load and provide aeration to the lagoon, aiding in the overall lagoon performance. Lower strength lagoons can place the REGEN BAF at the back end to ensure discharge limits are met. Both options would be a cost-effective alternative to replacing or upgrading existing underperforming systems.

The installation of the REGEN BAF pilot scale system at the blueberry processing facility in PEI was a success. The system was easily installed over a two-day period and ran smoothly for a summer and fall testing period. The REGEN BAF treatment system would benefit Wyman’s if operated in conjunction with their current lagoon. The BAF could operate up to 8 months per year without energy for heating wastewater where it could discharge back into the lagoon. The BAF could remove up to 11 kilograms BOD per day (or more than 40 kilograms COD per day) using a 40-foot full scale REGEN BAF system and discharge aerated wastewater back into the lagoon, which would boost the lagoon performance.

Conclusion:

Seasonally operated lagoons would benefit from the REGEN BAF running for the full 8 months and discharging back into the lagoon. This would help aerate the lagoon as well as remove a significant amount of BOD to easily achieve discharge requirements by the annual discharge date. Wyman’s of PEI could either discharge earlier in the year or over a smaller discharge area saving on the cost of irrigation equipment.

This testing has shown that the REGEN BAF can be used to supplement existing underperforming lagoons. The REGEN BAF can be operated in one of two ways. (1) It can be placed as a polishing step at the effluent of a lagoon to treat the effluent contaminants to below discharge limits, or (2) it can be used in parallel to the lagoon to recirculate partially treated, aerated wastewater back into the lagoon to help reduce the load and increase the processing capacity of the lagoon.

REGEN BAF is a modular, easily installed, cost effective solution for upgrading existing underperforming wastewater lagoon systems.