Industrial loading from two new local breweries was identified as a potential issue for the Montague wastewater treatment plant (WWTP). The facility manager wanted to quantify if these new businesses were contributing to excess organic loading into the facility and explore if they could work with the local industry to mitigate the impacts of discharge to the municipal collection system.

Having an understanding of the impact and timing of additional organic loading at the facility was important to ensure the facility maintained optimal performance. Three Rivers staff required a monitoring platform that was easy to install, had minimal maintenance requirements, and would provide real-time data with automated alerts and historical data storage capabilities. Being able to track daily trends while getting alerted in real-time to influent abnormalities is key for the operations team to track industrial discharge events and provide clear insight that could be communicated to the industrial clients.

The SENTRY monitoring platform was installed on the influent of Montague WWTP to help understand normal loading and identify the impact of industrial discharge events entering the facility. The facility is a return activated sludge (RAS) plant that services a community of 2,000 persons and some small industrial clients.

SENTRY sensors were installed on an influent pipe of the facility. Real-time data was collected for 12 months. Real-time alerts, historical datasets and aggregated data were used to identify weekly trending and pinpoint specific times of the day to expect additional loading from the industrial clients.

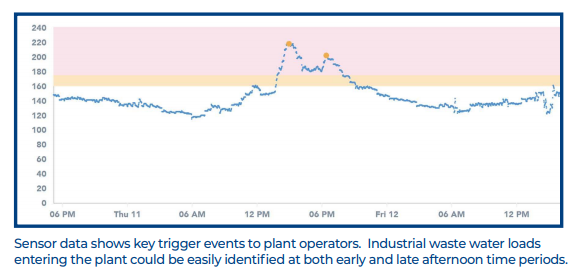

Operators were able to view clearly when higher organic concentration wastewater was entering the plant. SENTRY provided a real-time, always-on monitoring service with alerts set to notify operations of abnormal and significant increases in biological activity. Having this real-time notification allowed operators to get a very clear understanding of timing on key industrial discharge trigger events. This data became powerful as it clearly pin-pointed recurring parts of the day and week when events would take place.

The SENTRY data helped the facility clearly communicate the impact and timing of the additional organic loading to the local breweries. Using this information, the breweries were able to enact on-site solutions to reduce the strength/quantity of high organic waste discharge and decrease their impact on the treatment facility.

“SENTRY is always-on and requires very little maintenance. We use the platform to understand the impact of industrial discharge events at the plant. The combination of real-time alerts and the online dashboard provide the wastewater operations team a significant improvement on our ability to monitor plant performance and identify key imbalance events,” said Allan Greene, supervisor for sewer and water at Montague WWTP.

Having clear and reliable SENTRY data was helpful in building industrial client engagement, and is allowing the parties to cooperate in brewery wastewater management in the interest of their community.

For more information, please contact Patrick Kiely at [email protected].